The production of corn germ oil has long been a subject of interest for both nutritionists and food scientists, particularly concerning the relationship between extraction temperatures and the preservation of unsaturated fatty acids. As consumers increasingly prioritize health-conscious choices, understanding how processing methods impact nutritional quality becomes crucial. The delicate balance between efficient oil extraction and maintaining beneficial fatty acids presents an ongoing challenge for manufacturers.

Corn germ oil stands out among vegetable oils due to its high concentration of unsaturated fatty acids, particularly linoleic acid (omega-6) and oleic acid (omega-9). These compounds contribute significantly to the oil's reputation as a heart-healthy option. However, the stability of these valuable nutrients during the extraction process remains a critical concern. Traditional methods often involve heat application to improve yield, but this approach may compromise the oil's nutritional profile.

Extraction temperature emerges as the pivotal factor influencing both the quantity and quality of the final product. Lower temperature pressing, typically below 60°C, better preserves heat-sensitive compounds but results in reduced oil yield. This cold-pressed approach maintains higher levels of vitamin E and phytosterols while protecting the delicate structure of polyunsaturated fats. The trade-off between yield and nutrient preservation continues to shape industry practices.

Industrial-scale production often employs temperatures ranging from 80°C to 120°C to maximize efficiency. While this increases output, research indicates progressive degradation of unsaturated fatty acids at these elevated temperatures. The degree of damage correlates directly with both temperature intensity and exposure duration. Notably, linoleic acid demonstrates particular sensitivity to thermal stress, with studies showing measurable reduction when extraction exceeds 90°C.

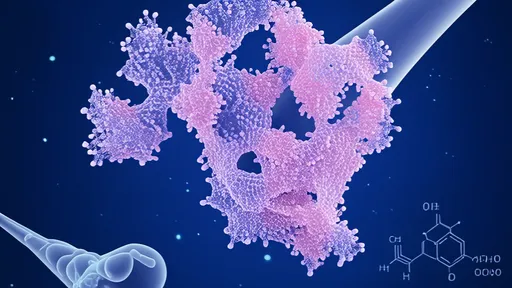

The molecular transformation of fatty acids under heat involves complex chemical processes. Elevated temperatures accelerate oxidation, leading to the formation of free radicals and peroxides. This not only diminishes nutritional value but also affects the oil's sensory qualities and shelf life. The degradation follows distinct patterns - first affecting the most unsaturated bonds, meaning omega-3 and omega-6 fatty acids suffer earliest and most severe damage.

Modern extraction technologies attempt to reconcile these competing priorities. Some processors now utilize multi-stage systems that combine mechanical pressing at moderate temperatures with subsequent solvent extraction. This hybrid approach aims to balance yield with quality preservation. Advanced monitoring systems allow precise temperature control throughout the extraction process, minimizing thermal stress on sensitive compounds.

Emerging research suggests that pre-treatment of corn germ before pressing significantly influences temperature effects. Enzymatic treatments or controlled moisture adjustment can reduce the required extraction temperature while maintaining satisfactory yields. These methods show promise for better preserving unsaturated fatty acids, though they require additional processing steps and equipment investment.

The storage stability of corn germ oil also relates directly to its extraction temperature history. Oils produced through high-temperature methods often contain more oxidation products initially and demonstrate faster degradation during storage. This creates a compounding effect where thermal damage during processing reduces the product's resistance to subsequent quality decline.

Nutritional analyses consistently reveal measurable differences between cold-pressed and conventionally processed corn germ oils. Beyond fatty acid profiles, these differences extend to antioxidant content and overall oxidative stability. The nutritional advantage of lower-temperature processing becomes particularly relevant for consumers using the oil uncooked, as in dressings or dips, where the preserved nutrients remain fully bioavailable.

Industry standards and regulations continue to evolve regarding temperature claims on corn oil products. The term "cold-pressed" now carries specific legal definitions in many markets, typically requiring extraction below 50°C. Verification of these claims presents challenges, as post-extraction handling can also affect final quality. Sophisticated analytical methods like gas chromatography and mass spectrometry enable more accurate assessment of thermal impact on oil composition.

Consumer education plays an increasingly important role in this discussion. Many buyers remain unaware of how processing temperatures affect their cooking oil's nutritional value. Transparent labeling and clear communication about extraction methods could help bridge this knowledge gap. Some premium brands now highlight their low-temperature processing as a key selling point, though this typically comes with higher price points.

Future developments in corn oil extraction will likely focus on optimizing the temperature-yield-quality triangle. Novel technologies like supercritical fluid extraction or ultrasound-assisted pressing may offer solutions. These methods show potential for efficient extraction at lower temperatures, though scalability and cost-effectiveness remain hurdles for widespread adoption.

The scientific community continues to investigate the precise mechanisms of fatty acid degradation during oil processing. Recent studies examine not just the quantity of preserved unsaturated fats, but changes in their molecular configuration under thermal stress. Cis-trans isomerization, while less common in plant oils than hydrogenated fats, still occurs to some degree during high-temperature extraction.

From a global perspective, the implications of extraction methods extend beyond nutrition. Energy consumption and environmental impact vary significantly between low-temperature and conventional processing. As sustainability concerns grow, the industry must consider both the nutritional and ecological footprints of different production methods.

Practical recommendations for manufacturers continue to emphasize finding the optimal balance for their specific market. For mass-market products where price sensitivity dominates, moderate-temperature extraction may remain standard. For premium health-focused segments, investment in low-temperature technologies could provide competitive advantage. The diversity of corn varieties and growing conditions further complicates universal recommendations, as different germ compositions respond uniquely to processing conditions.

Ultimately, the corn oil industry faces the classic challenge of balancing efficiency with quality. As research provides clearer understanding of temperature effects on unsaturated fatty acids, processors gain better tools for making informed decisions. The coming years will likely see continued innovation in extraction technologies, driven by both consumer demand for healthier options and the industry's pursuit of sustainable practices.

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025