The texture of ice cream is a delicate balance between smooth creaminess and undesirable graininess. Among the many factors influencing this texture, lactose crystallization stands as a critical yet often overlooked element. When lactose crystals grow beyond a certain size, they impart a gritty or sandy sensation on the palate, detracting from the luxurious mouthfeel that defines premium ice cream. Understanding and controlling lactose crystallization is therefore essential for manufacturers aiming to deliver consistently superior products.

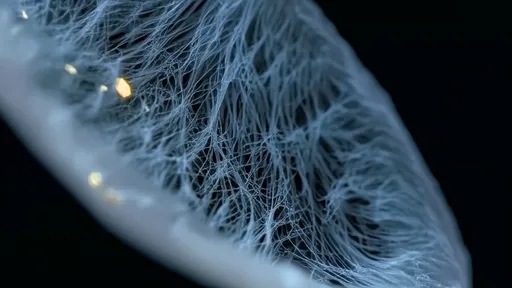

Lactose, the natural sugar found in milk, exists in a dissolved state in the liquid phase of ice cream mix. However, as the mix freezes, water turns into ice, concentrating the remaining solution. This increased concentration can push lactose beyond its solubility limit, forcing it to crystallize. The size and quantity of these crystals determine whether they will be perceptible to the tongue. Crystals smaller than 15 micrometers generally go unnoticed, while larger ones create that telltale sandiness.

The rate of freezing plays a pivotal role in lactose crystallization. Rapid freezing, as occurs in modern ice cream production, tends to produce numerous small crystals rather than fewer large ones. This is because the quick temperature drop leaves little time for molecules to organize into larger crystalline structures. However, even with fast freezing, improper storage temperatures during distribution and retail display can allow small crystals to grow over time through a process called Ostwald ripening.

Composition of the ice cream mix significantly affects lactose behavior. Higher milk solids content naturally means more lactose present, increasing crystallization risk. However, other ingredients can influence this process. Sugars like sucrose and glucose compete with lactose for water molecules, effectively reducing lactose's ability to dissolve. Stabilizers, while primarily used for texture and melt resistance, can also interfere with crystal growth by physically obstructing lactose molecules from joining existing crystals.

Processing techniques offer additional control points. Homogenization breaks down fat globules but also distributes milk proteins more evenly, some of which may interact with lactose molecules. Aging the mix before freezing allows for complete hydration of proteins and stabilizers, creating a more uniform environment that can help regulate crystallization. The dasher speed and design in the freezer barrel affect how quickly heat is removed and how much mechanical shear is applied, both factors in crystal formation.

Storage conditions post-production often prove to be the undoing of carefully controlled crystallization. Temperature fluctuations cause partial melting and refreezing, which encourages crystal growth. Even in constant subzero temperatures, the extremely concentrated unfrozen portion continues very slow molecular movement that can lead to crystal enlargement over months. This explains why even properly manufactured ice cream can develop sandiness after prolonged storage.

Advanced formulations now incorporate novel approaches to lactose management. Some manufacturers add beta-galactosidase enzyme to hydrolyze lactose into its simpler, more soluble components glucose and galactose. Others use specialized milk protein concentrates that bind with lactose molecules. Certain stabilizer blends specifically target crystal inhibition without affecting other texture parameters. These technological solutions allow for greater flexibility in formulation while maintaining texture standards.

Consumer expectations continue to drive innovation in this area. As palates become more discerning and premium products command market share, the tolerance for any textural imperfections diminishes. What might have been acceptable graininess a decade ago now qualifies as a product defect in high-end segments. This pushes manufacturers to refine their control over lactose crystallization through better ingredients, more precise processing, and smarter distribution protocols.

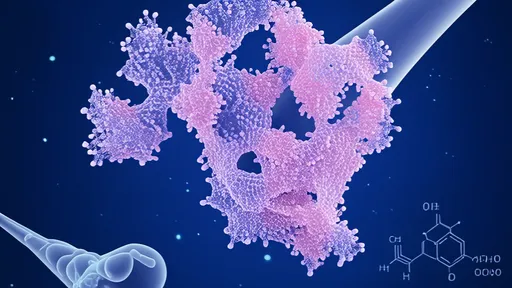

The interplay between lactose behavior and other ice cream components creates complex dynamics. Fat globules and air cells occupy physical space that could otherwise be taken by growing crystals. Emulsifiers affect how water is distributed in the matrix. Even the minor constituents like minerals from milk can influence crystallization kinetics. This complexity means that lactose control cannot be viewed in isolation but must be considered as part of the complete system.

Practical testing methods have evolved to predict sandiness potential. Accelerated shelf-life studies subject samples to controlled temperature cycling while microscopic analysis tracks crystal growth. Sensory panels train specifically to detect early-stage graininess. Some manufacturers now use specialized software to model crystallization behavior based on formulation inputs, allowing for virtual testing before physical production.

Looking forward, the science of lactose control continues to advance. Nanotechnology applications may offer ways to direct crystal formation at molecular levels. New analytical techniques provide real-time monitoring of crystal size distribution during production. As the understanding of lactose's role in ice cream texture deepens, manufacturers gain more tools to consistently deliver that perfect, velvety smoothness consumers crave.

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025